Partners

Cincinnati Test Systems Inc (CTS)

The ARM is since 1999 the Cincinnati service center for South America. This is a partnership of more than ten years based on reliability and excellence in service.

Cincinnati Test Systems (CTS) is a world leader in the design and manufacture of standard and custom leak test systems and machines. Leak testing is critical to ensuring proper product quality, safety, and performance. There are several methods of leak testing, each with different characteristics that make it favorable for specific applications.

Cincinnati Test Systems manufactures a leak test machine for every industry, from medical to automotive, defense to aerospace, and beyond. For over 30 years, we’ve been providing pressure decay, vacuum decay, mass flow, helium leak, and other testing systems for customers all around the globe. CTS’ leak test machines have earned a reputation for excellence by delivering best-in-class performance and advanced

LPS (Leak Testing Equipment)

ALPS has delivered more than 2,500 leak test machines and 10,000 leak test circuits with the current population of machines leak testing approximately 50 billion containers and packages annually.

Rotary Leak Testers

ALPS’ industry leading Rotary Leak Testers provide the highest speed and accuracy approach for on-line leak testing. Rotary testers are used for 100% on-line inspection to verify container integrity by testing empty containers, or to verify seal integrity by testing filled containers.

ALPS currently produce standard rotary testers with 4 to 30 test stations for speeds up to 1,200 parts per minute. Larger rotary testers are possible to achieve higher speeds and/or greater leak test sensitivities.

The ALPS Speed-Glider is a multiple-station continuous-motion linear leak tester for empty containers. The system is designed for inspection speeds up to the 250 Containers-Per-Minute (15,000 Containers-Per-Hour) range.

Speed-Glider 4.5 four station leak tester

ALPS offers Rotary Leak Testers for Filled & Sealed Products, for 100% on line seal integrity testing. Configurations are available in up to 30 test stations, and speeds currently up to the 1,200 Containers Per Minutes (72,000 CPH) range.

The seal integrity test is performed by ALPS Leak Test Controller (LTC) Pressure Decay or Vacuum Decay test heads on each station. Each LTC incorporates a custom probe head to seal an enclosed volume around the container seal

ALPS NexGen Rotary for Seal Integrity testing of filled & sealed containers

The ALPS SC Linear indexing conveyor leak tester is an excellent general purpose empty container leak tester with a wide range of capabilities. The leak tester conveyor is fully integrated, with optional vacuum capability, and designed for optimal handling to ensure the most accurate leak test possible in addition to the highest speed capacity on a single test station.

The SC Linear leak tester speed and sensitivity capabilities depend on the container size and volume. Typical leak inspection speeds range from 10 to 30 Containers-Per-Minute (CPM) for larger containers (e.g. 4 to 5L); to 60 to 100 CPM for single-serve containers (e.g. 0.5L), up to the 180 to 200 CPM range for the very smallest pharmaceutical bottles (e.g. 20 to 40mL

SC Linear bottle leak detector

www.alpsleak.com

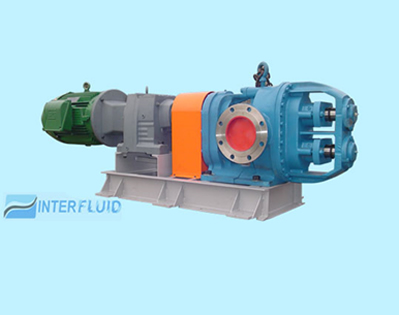

Interfluid – Solution in Moving Fluids

Still, over the years we have been specializing in the design, development and manufacture of “SYSTEMS AND SOLUTIONS TO DRIVE FLUID” and today we are one of the best options in the market.

We also incorporated to our line, indispensable for the construction and operation of these systems with a wide range of mechanical and electronic products items that allow complete automation and control of these systems.

Still, we highlight the great performance they are having with companies in the field of Paper / Pulp, Chemicals & Petrochemicals, participating in many projects with supplies process automation, for example, automatically control the injection of various products required for a physical reaction chemistry.

Viapol, PTI Power, BASF, Petrobrás, Invista, Dow Corning, Nalco, General Motors, Reichhold, Mabe, Texaco, VISCOFAN, Cellulose Argentina are some of the companies that can attest to the quality and reliability of INTERFLUID “SYSTEMS FLOW”.

www.interfluid.ind.br

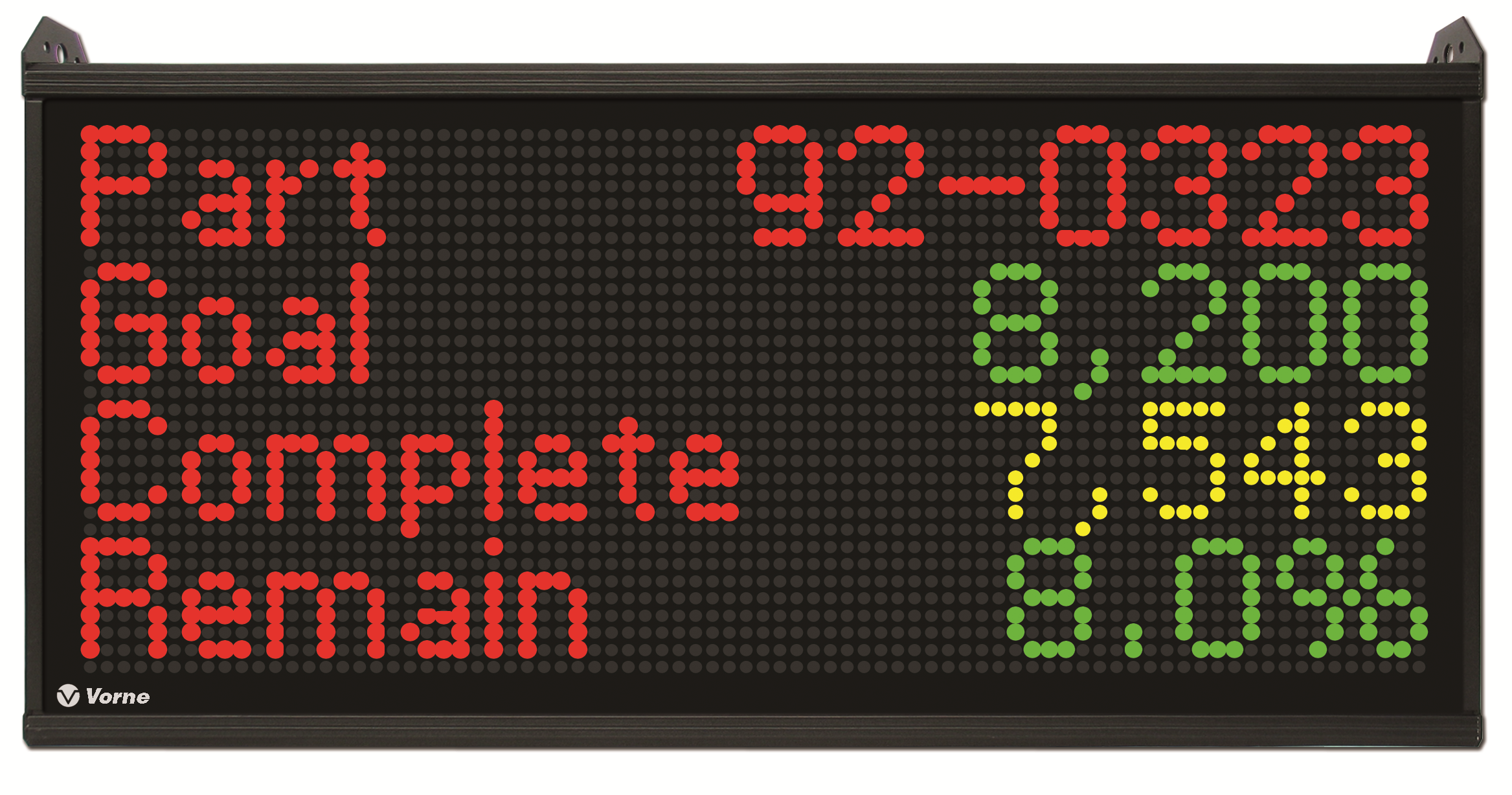

VORNE

Vorne is a company that since 1970 your passion (and obsession) has always been to provide productivity enhancing products that work harder, last longer and provide better value than anything else available! What this means to you – EXPERIENCE!

Vorne know that customers aren’t just looking for a display, they seek enhanced productivity, increased morale, improved communications or simply the ability to know how many units were produced this shift. We know what works and what doesn’t for most any industry and are happy to help you.

Meet XL – A device, a universe of information

What is XL?

XL is a new breed of device known as a Productivity Appliance™. It snaps on to your existing processes and immediately delivers real-time performance data to all levels of your company. A web-based interface means no software to install. And, it adds value to all levels of your company: Strategic, Tactical, and Operational.

VINCE Solutions and Technologies

Solutions Management Factory Floor

Deployment of advanced solutions for production management, simulation and production scheduling with finite capacity, automatic machine monitoring, management of OEE, data collection, among others.

Tools to provide flexibility in production management, faster response time to the problems of plant floor information for continuous improvement, increased productivity, increased customer satisfaction, among many other benefits.

Advice and training to reduce production losses.

Technology is important, but people are the most important to achieve continuous improvement. And it is on the factory floors who are the people that will turn losses into profits. As important as the use of tools for advanced production management, training of operators, supervisors and managers is essential, as are agents of transformation of reality within the company.

Advisory services aim to train and track teams in the implementation of the 4 disciplines of execution of high performance:

- Focus on the most important

- Create a compelling scoreboard

- Transform vague goals into specific actions and

- Collection of mutual results.

Specific projects

ARM Automation coupled with VINCE unite knowledge of production engineering, automation, information systems (IT) and management experience in solutions for the factory floor. Also develop projects to meet the specific needs of its customers.

www.vince.com.br

MARCA Assessoria, health and safety

• Conceptualization of security;

• Electrical safety projects;

• Commissioning and start up;

• Assisted operation;

• Training;

• Final compliance report to NR12;

• Technical assistance.

www.marcasegurancadotrabalho.com.br