Machines / Special Devices

Laboratory of Metallurgy and Ceramic Materials / CTPP (IPT)

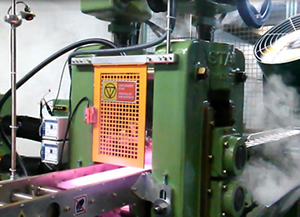

Application: Testing of rolling metallic materials in general for technological research.

Benefited sectors: iron and steel industry; metallurgical sector; the construction industry; port and railroad industry; support technology centers IPT.

The adjustment of the thickness was performed by servo drive allowing precise control of thickness.

A supervisory system was deployed to control, integration and data acquisition (SCADA) of the forming process (refrigeração1, rolling strength, gap between cylinders, rolling direction and count rolled parts).

Technical feasibility of fabrication of cement agglomerated with granite waste and BOF steel slag

This research intended to evaluate the utilization feasibility of waste materials or residues generated in the steelmaking process in substitution to regular resources to produce paving material for industrial and non industrial pavements in accordance with Brazilian Standard.

ARM participation:

Control system for dosing apparatus and mixing in slag pot.

Objective: To control the speed of the dosing thread and the reading of the scale (under the doser) by the supervisory system, making it possible to administer the feed rate of the material to be added to the slag pot.

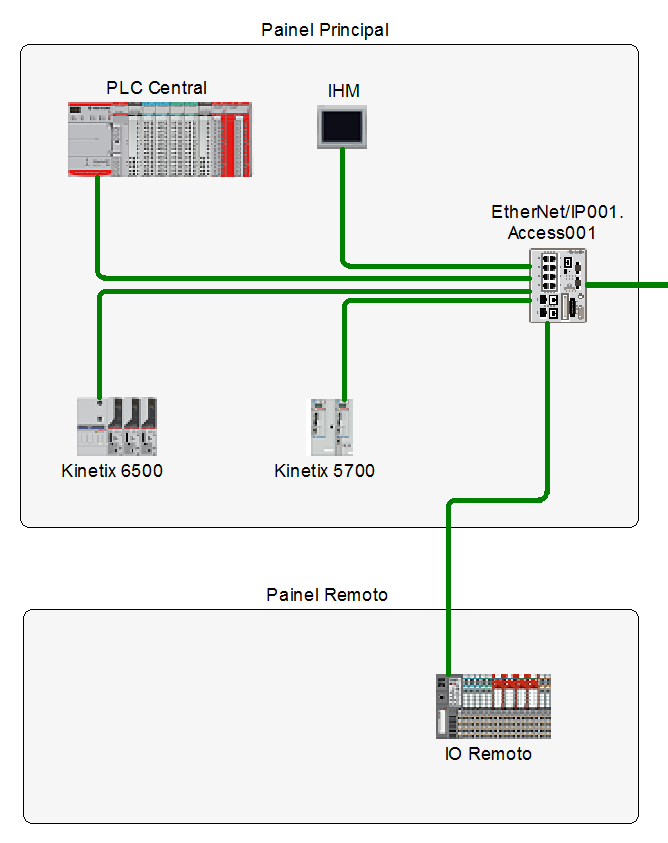

Linear Charger Project – Electrical assembly

Projects in partnership with SMS Group developing software and electrical projects.

SMS Group: Multinacional group specialized in repairing key components for the steel, aluminum, and non-ferrous industries. Included here are molds and segments for casters, mandrels, coilers, and complete drive systems for rolling mills and process lines.

Hardware used: Rockwell

- Compact GuardLogix 5380 Safety Controller;

- Graphic Terminal, Performance Model, Extended Features,10.4 in., TFT Color;

- Kinetix 5700 EtherNet/IP Servo Drives

Carding machine to prepare rolls of wool

Machine developed entirely in ARM, from design Mechanical, pneumatic and electric until the software operation and control.

In this photo, next, we observe the machine in production line.

Front view of machine described in the previous photo in the final process of mounting even in our factory.

More constructive detail of the machine adopting innovative solutions to control multi-axis synchronized and working in high gear over 3500rpm.

Leak testing equipment – Cincinnati Test System Inc.

Leak detection instrument, used in a device to test fuel pumps developed and manufactured in ARM Automation

Device to test for leaks fuel module

Front view, of all fasteners and sealing ring of a test module of fuel.

Leak test instrument for fuel module used in device

Test set double of flange and the fuel outlet fitting. The device has a four position rotary table controlled by servo drives and identification marking, hot stamping.

Thermoplastic structural welding machine

Machine used for welding structures of plastic lining and coating for automotive finishes. This machine uses 48 temperature zones with 64 points of puncture.

ARM Automation was responsible for electrical design and software Programmable Controller and Human Machine Interface, and security project.

Assembly line modules for fuel.

ARM has designed and built two assembly lines at the fuel modules which were installed in Caçapava SP and the other was exported to Mexico.

The installation and start-up was performed by field staff of the ARM.

Mechanical design

Mechanical projects are developed in Solid Works, one of the most advanced tools for making mechanical drawings today.

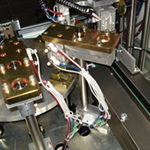

Machine for testing electrical relays in automotive

Beside, there is a detailed view of the machine for testing electrical relays in automotive.

This machine was designed, built and installed by a team from ARM Automation.